by

Lauren Dubinsky, Senior Reporter | August 22, 2014

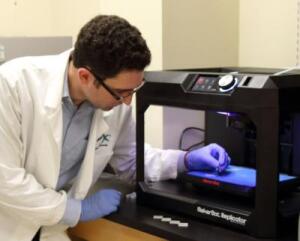

Jeffery Wesiman, a doctoral

student at Louisiana Tech

University, uses the 3-D

printer to create custom

medical implants

Courtesy of Louisiana

Tech University

Researchers at Louisiana Tech University developed a new method for targeted drug delivery using consumer-grade 3-D printers to create custom medical implants composed of antibacterial and chemotherapeutic compounds.

The current drug delivery systems use antibiotic implants, or "beads," comprising bone cements that are mixed by the surgeon during the surgery. But they contain carcinogenic substances, and they're also a form of Plexiglas, which can cause problems.

"The problem with Plexiglas is that it doesn't dissolve, so once the antibiotics are released or presumed to be released, the surgeon has to go in for a second surgery and remove those beads," Dr. David Mills, professor of biological sciences and biomedical engineering, told DOTmed News.

But with the 3-D printing method, the researchers created filaments that are made of bioplastics, which can be reabsorbed by the body and prevent the need for additional surgery.

Additionally, when the surgeon mixes the material together, the Plexiglas polymerizes, which creates a high temperature and causes some of the surrounding tissue to die. It also limits the use of some types of materials and drugs that are heat sensitive. But the bioplastic material that the 3-D printed implants are made of don't cause a heat issue.

The current drug therapy systems also require large systemic drug doses, which can cause negative effects for the patient. "They're just trying to get as much antibiotic in you as possible so that they get some of that to the affected site," said Mills. "The negative impact is that for some patients that can lead to toxicity issues both in the kidney and liver."

However, the implants created by the 3-D printer have a better surface area and increased drug delivery and control. That allows for more localized treatment so there's no need for large systemic drug doses.

Personalized medicine is the direction that the industry is moving in, and Mills believes that 3-D printing custom medical implants will play a role in it. "Rather than a one-size-fits-all, you can custom-tailor the antibiotic or chemotherapeutic treatment specifically for that patient," he said.

The surgeons are able to work with the pharmacists to design how much antibiotic is in the implant and how long it needs to deliver the dosage, and then they can program that all into the 3-D printer.

The researchers have submitted a patent for the method and have also formed a company called Organic Nano. They are currently looking for partners in order to commercialize it.

Back to HCB News